Retail Product for Fox Wedge Furniture

The Alex

Platform Bed

An insight into the

Creative Design Process

About This Project

Japanese-Inspired Craft using Modern Methods

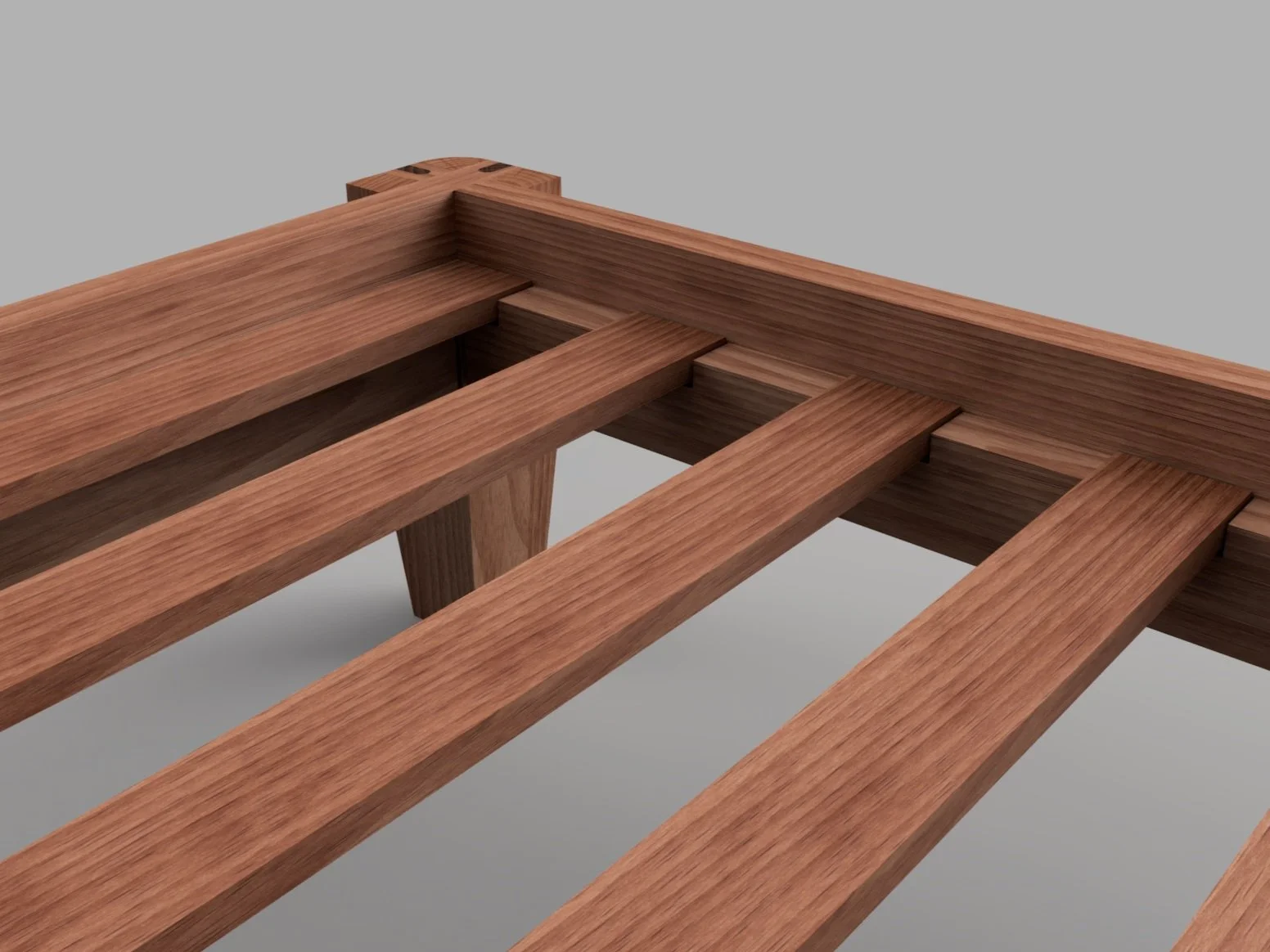

The castle joint is a staple of Japanese woodworking. Featuring three interlocking pieces for strength and beauty, traditional construction is time- and labor-intensive. CNC manufacturing streamlines the process, making the final product cheaper without sacrificing quality.

Challenge 1:

The Chunky Legs

Not bad, just not great.

Similar castle joint beds are functional but bulky and hard to manufacture. I redesigned it with a clean, minimal Japanese-inspired look and optimized it for CNC production.

Before

After

The Solution

Split the leg into three pieces, machine them from one board for a perfect match, align with dowels, glue, sand, and finish. The result? A precise castle joint with minimal effort.

This method allows for all four legs (plus the leg used for the center support rail) to be machined at the same time, cutting production time down and making setup easier.

Challenge 2:

Slappy Slats

The bed was loud.

The slats clacked with every movement—a common issue in beds with slat supports. We envisioned a hardware-free solution using joinery to secure them while avoiding felt or synthetic materials.

Version 1

Our original design nested slats in side rail slots, but while it was easy to assemble, it was still prone to clacking.

The Solution

Use canvas webbing to secure the slats in slots along the rails. Pull the webbing tight, pin it, and voilà—tension holds the bed square.

Slots along the rails capture the top and bottom of each slat.

Slats enter the slot via a gap halfway across the bed rail.

Challenge 3:

The Headboard

“Does it have a headboard?”

I was asked this approximately 3,200 times during one tradeshow. Originally we had no intention to design a headboard, but the people spoke and said they needed something to lean against.

Rigid ideas lead to clunky solutions.

I initially refused to alter the bed frame. My team wanted to attach support legs by drilling through the bed rails, but I wanted the front and back rails to be exactly the same.

After brainstorming dozens of alternative solutions (and prototyping a few of them), I realized that I needed to be more flexible in my design intent in order to create a better quality product. The simplest and most elegant solution was sending a bolt through the rail to prevent wobbling and structural damage.

The Solution

To adhere to this conclusion while staying true to our values, we designed the headboard to use joinery where possible and hardware where essential. The final design features elongated legs with shoulders for the headboard to rest on that is then bolted in place, with the additional support legs hugging the frame for extra support. This allows wood movement and creates a sturdy, secure solid wood headboard that’s an absolute showstopper.